If and when coating eventually exhibits sign of put on it could actually easily be coated over itself with only a single coat. Can simply be repaired by merely applying more materials over damaged space. ArmorTrak reactivates itself and bonds to the earlier coating. ArmorTrak rubberized epoxy has confirmed to be a fantastic alternative for industrial kitchen floors which can be subject to oil & grease spills and impacts from dropped pots, pans and dishes.

Vent-E bridges the gap between protective and seamless coatings and different resinous flooring techniques. The permeability of Vent-E permits moisture to maneuver by the slab and coating without inflicting unsightly blemishes or failures. Vent-E offers many of the identical features of other protective epoxy flooring methods: stain and put on resistance, mud prevention and easy maintenance. Most solely need soap and water, and some may be cleaned well sufficient with water alone. Occasional scrubbing and buffing is needed for best look, but aside from that, no special cleansing agents or techniques are wanted. The exact strength of sturdiness of the floor depends on the fabric coating it, but all resin-coated floors are exceptionally robust and resistant to wreck. They’ll stand as much as plenty of abuse, with out chipping or cracking- which is critical in industrial spaces. Nevertheless, the cross-sectional view reveals the presence of some voids in the coating and some areas of disengagement between the CR particles and the resin. The distribution of the different sizes of CR particles within the resin appears to be sufficient while the interface between the coating and substrate has small areas of discontinuities.

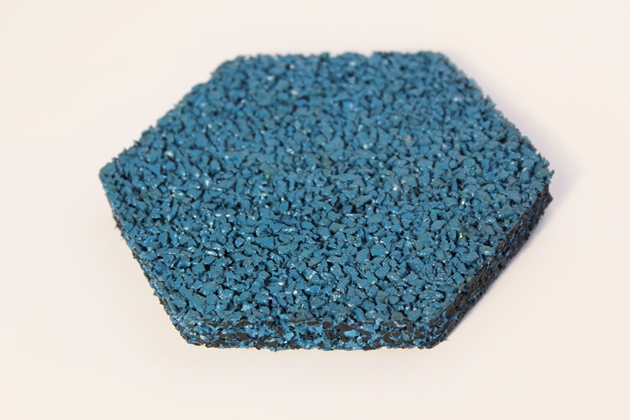

ArmorTrak is an industrial rubberized epoxy that’s totally versatile, slip-resistant and a hundred% waterproof. ArmorTrak is not only common paint, it is a liquefied polyurethane membrane with proprietary self-contained dehydrated rubber granules that kinds a novel rubber epoxy ground coating that is aesthetically pleasing, textured, slip resistant and tremendous durable. ArmorTrak rubberized epoxy will chemically and permanently bond to most clear and dry surfaces. These embody, but are usually not limited to, concrete, wooden, fiberglass, metallic, rubber, ceramic tiles, porcelain tiles. View sustainability information here. Your request has been submitted. The contractors can be involved with you. Add these contractors, too? GAF recommends getting a minimum of 2 estimates. By checking this field and clicking Submit I settle for the next phrases and situations. Find a industrial distributor close to you. Find a GAF certified contractor close to you. All Rights Reserved. | GAF CA | GAF U.S. Hour forty eight: Your new roof is full! Your new roof is finished! RVs, being significant investments, require meticulous care, particularly their roofing programs. Liquid Rubber presents an modern, efficient, and sustainable solution for those looking for to refurbish their RV roofs with out a complete alternative. When contemplating an RV roofing solution, Liquid Rubber supplies you with all of the products you want, from cleansing to the coating, and stands out as the compelling choice. For detailed directions on the Liquid Rubber software, kindly consult the official RV Roof Coating Utility Information. At RV LIFE, we build instruments that make camping easy. We run a community of websites and companies that assist RVers get essentially the most out of their adventures.

Too usually water is allowed to seep via the small crack where the flooring meets the wall. Whether or not rain on a porch or wash water in a manufacturing facility lunch room, liquid and microorganisms push below the trim and behind the wall where they fester and may damage the construction or create an unhealthy environment. ] on pure metals showed that erosion resistance is straight proportional to hardness. For the newly developed coatings introduced here, it was discovered that the erosion price will increase with rising bulk hardness. To grasp the erosion mechanism, SEM images of the eroded surfaces have been captured and presented in Figure 4. Those photos revealed proof of fabric slicing, shredding and localized fractures on the eroded coatings. On the whole, the erosion mechanism depends on the ductility and brittleness of the material. In ductile materials, the impression of strong particles causes localized plastic deformation and finally results in failure. Surface cleansing: Prioritize eradicating any dirt, debris, or old caulking to make sure optimum adhesion. Harm evaluation and repair: Conduct a radical inspection for cracks or damage. Apply patches or sealants for minor issues, making certain they are dry earlier than proceeding. Space masking: Utilize painter’s tape to safeguard vents, skylights, and different components not meant to be coated while applying a brand new RV roof.

Most mobile dwelling repair professionals advocate a neoprene or polyurethane flashing sealant. Add it to the seams and across the vents and let it cure. You should definitely comply with the producer’s directions. As soon as the flashing has cured, you will brush on the coating in layers. White elastomeric coating is advisable because it displays sunlight. Make sure you comply with the producer’s directions; some merchandise require a preliminary primer earlier than the sealer coat is applied. SANI-TRED PermaFlex™, is a liquid polyurethane coating that penetrates deeply into and will bond completely to correctly prepared concrete, wood, покрытие детских площадок резиновой крошкой цена aluminum, steel, and some plastics, as well as most all different standard building materials. PermaFlex won’t ever bubble, chip, peel, crack, or delaminate from vehicle site visitors, publicity to extremes of ambient heat up to 250°F cold, or Detrimental Hydrostatic Stress. Our PermaFlex liquid rubber coating is environmentally safe, solvent free, non-flammable, and low VOC. PermaFlex is extremely durable with 2,030 psi tensile strength. This rubber liquid sealant might be brushed, rolled and even sprayed on. Second coat: To achieve optimum durability and protection, it is strongly recommended to apply a second heavy coat of Liquid Rubber. After making use of the second coat, permit a full 24 hours for the coating to cure completely. Though the surface might seem dry sufficient for gentle walking in your new RV roof, prolonged curing will guarantee optimal performance.